Non-Destructive Testing

- Industrial Radiography using Gamma-Ray

- Steel Wire Rope Testing – MFL

- Magnetic Particle Inspection

- Dye Penetrant Inspection

- Ultrasonic Testing and Thickness Measurement (UT and UTG)

- Eddy Current Inspection

- Visual Inspection

- Remote Visual Inspection with aid of videoscopes

- Positive Alloy Material Identification

- Ferrite Testing

- Hardness Testing

Applications

- Inspection / Monitoring / Maintenance

- Condition Assessment

- Fabrication Quality Check

– including according to MOM regulatory requirements for new fabrications

- Failure Investigation

- Material Verification

Industrial Radiography

Radiographic Testing (RT) uses gamma rays to examine the internal structure of materials or components without causing damage. It works by utilizing the property that different materials absorb radiation at different rates, allowing the detection of hidden flaws and discontinuities.

Magnetic Particle Testing

Magnetic Particle Testing (MT), also known as Magnetic Particle Inspection (MPI), is a NDT technique used to find surface and slightly subsurface flaws in ferromagnetic materials such as iron, nickel, cobalt, and their alloys (like steel).

Liquid Penetrant Inspection

Liquid Penetrant Testing (PT) is a widely used, cost-effective NDT method for detecting surface-breaking defects in non-porous materials. The technique relies on the principle of capillary action to draw a highly visible or fluorescent liquid into flaws, making them visible to an inspector. Indications of a wide variety of discontinuity sizes can be found, regardless of the configuration of the test object and regardless of discontinuity orientations.

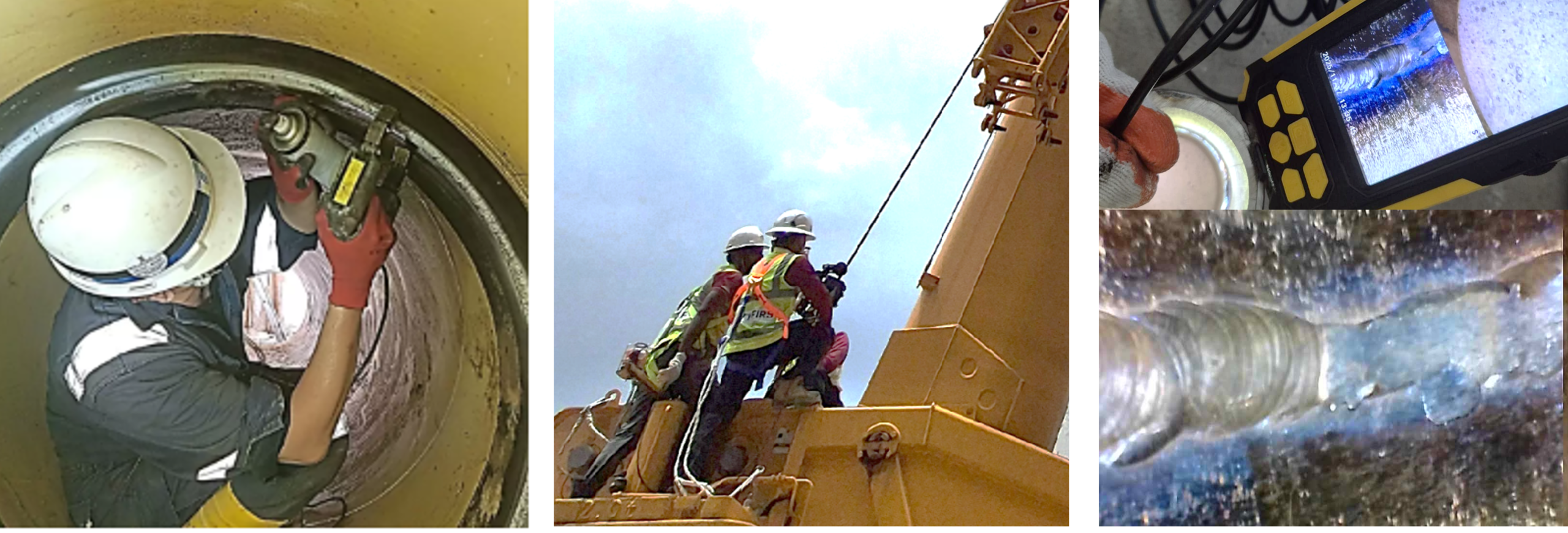

Steel Wire Rope Testing – MFL

Steel wire rope testing inspects wire ropes by using magnetic flux leakage principle and basing on the characteristic of magnetic memory of Ferro-magnetic materials.

This innovative technology provides a constructive and effective inspection solution to check the integrity of wire ropes, detecting defects in steel wire ropes that are not visible through traditional visual inspections.

It can localize defects on both external surface and internal of the rope that are associated with broken wires, corrosion pits, wear, corrosion, fatigue.

This technology is used across a wide range of industries on lifting equipment (such as cranes – mobile, gantry, port etc, ASRS, elevators), cableway, steel cord conveyor system, power transmission and mining systems.

Ultrasonic Testing and Thickness Measurement (UT and UTG)

Ultrasonic testing (UT) is a non-destructive method that uses high-frequency sound waves to examine materials for internal flaws, measure thickness, and assess integrity.

Ultrasonic thickness gauging (UTG) is used to inspect the thickness of a material of component. It works by sending high-frequency sound waves into the material with a transducer and measuring the time it takes for the waves to reflect back from the opposite surface. This allows for accurate thickness measurement, corrosion monitoring, and quality control without damaging the part.

Eddy Current Inspection

Eddy current testing is a non-destructive method using electromagnetism to detect flaws like cracks and corrosion on or near the surface of conductive materials. Its applications include material analysis (conductivity, hardness, coating thickness), and defect detection in industries such as aerospace, automotive, and power generation. It is a versatile, non-contact test that can be used on complex shapes and provides immediate feedback. During in-service inspection paint removal is not required. It can only be used on conductive materials and is best at finding surface or near-surface flaws.

Ferrite Testing

Ferrite testing is a non-destructive or destructive evaluation technique used primarily on austenitic and duplex stainless steels to measure the volume percentage or Ferrite Number (FN) of ferrite content. This is critical for ensuring proper mechanical properties, corrosion resistance, and preventing cracking in materials, especially in welds.

Hardness Testing (UCI and Leeb)

UCI (ultrasonic contact impedance) and Leeb hardness tests are portable and NDT methods to measure the hardness of materials. Both methods can be performed on site without removing the parts to be tested.

UCI hardness test uses an oscillating probe to measure the material’s hardness by evaluating the Vickers indentation electronically according to the change in its vibration frequency when the probe is pressed into the material.

Leeb hardness test involves using a portable device to launch a small impact body against the test surface, and the material’s hardness is measured by calculating the energy loss of the impact body after impacting upon a metal.

Positive Alloy Material Identification

Positive Material Identification (PMI) is used to verify the elemental composition and grade of a metallic alloy. It is crucial for quality control and safety compliance, as it prevents operational failures and hazards that could result from using the wrong material.

PMI is commonly performed on-site using portable devices like X-ray fluorescence (XRF) analyzers, which use X-rays to stimulate a material and then analyze the emitted radiation to determine its elemental makeup, and Spark Optical Emission Spectroscopy (OES), which analyzes the light emitted from a spark created by striking the metal.

Visual Inspection, Remote Visual Inspection with aid of Videoscopes

Visual testing is the observation of a test object, either directly with the eyes or indirectly using optical instruments, by an inspector to evaluate the presence of surface anomalies and the object’s conformance to specification. Instruments such as boroscope, videoscope can be used to facilitate the inspection.