Material Assessment

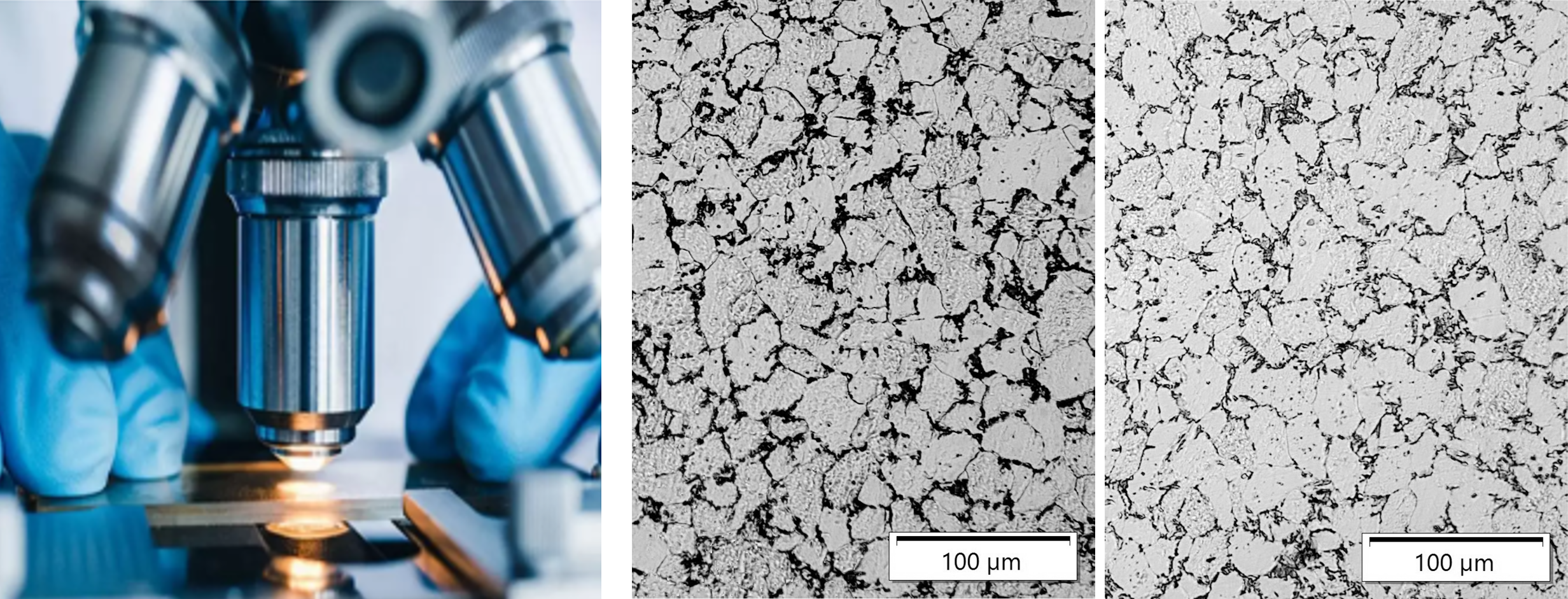

In-Situ Metallurgical Assessment

In-situ metallurgical assessment is an inspection technique that involves field replication of the microstructures of materials and equipment without removal of the parts from site to check the material condition. This technique is usually coupled with in-situ hardness testing as a complementary check on the material properties.

This serves as an important aspect of asset integrity management e.g., for evaluating microstructures of plant equipment such as boilers, HRSG, piping, heaters and reactors, when conducting a Fitness for Service evaluation. It also aids in decision making when considering for continued usage, repair or replace.

It can also be used for checking

-

-

-

- Material degradation/damage mechanisms/microstructure transformation

– over time in service, after welding/heat treatments, after incidents - Crack characteristics

– this technique can assist to confirm/supplement NDT findings (e.g. MPI/PT, UT results) by identifying the nature of the flaw

– for e.g. whether a crack is transgranular or intergranular in nature - Material defects

- Material degradation/damage mechanisms/microstructure transformation

-

-

Failure Analysis

Failure analysis is a systematic process to determine the failure/damage mode and mechanism of a material and component’s failure and the cause of the failure. It serves to identify factors like design flaws, issues in manufacturing quality, operation and/or maintenance, with the aim of rectifying and preventing future matters and improving product/process quality.

We have performed failure cases from across various types of

⇒Components/systems

⇒Materials (metallic/non-metallic)

⇒Industries

Material Testing

Material testing is the process of examining the physical, mechanical, and chemical properties of a material for the purpose of

- Quality Assurance

- Performance Evaluation

- Safety & Compliance

- Research & Development

- Failure Analysis

This can be achieved through various methods, which can be destructive or non-destructive

⇒Mechanical (tensile, impact, hardness…)

⇒Metallurgical

⇒Composition (PMI, wet chem, EDX, XRD, FTIR…)

⇒Chemical testing

⇒Thermal testing

X-Ray Computed Tomography / 3D Scanning

X-ray computer tomography is a computer-aided tomographic process that uses irradiation and captures a variety of X-ray images from different angles around the object to produce three-dimensional internal and external representations of the scanned object.

Some key applications of industrial CT are

- Capture and visualize complex geometries and/or internal features/geometries

- Flaw detection

- Failure analysis

- Metrology

- Assembly information

3D scanning is the process of converting a physical object into a digital format by capturing the shape, geometry and appearance from various angles and reconstructing into a 3D model.

The acquired 3D data can be used for

- Quality control: quantifying geometrical changes such as deformation

- Manufacturing: first article inspection

- Prototyping: creating digital models for records of new products or modification of existing ones

- Reverse engineering